Truth About One-Day Systems

“One-Day Polyurea” Coating Systems: Speed and High Quality Don’t Intersect

The demand for concrete coatings is on a steep incline. This has triggered an influx of new businesses in the concrete coating industry, eager to cash in on the escalating interest. A large number of contractors have jumped aboard the “one-day polyurea” or “one-day polyaspartic” bandwagon, drawn by clients seeking rapid one-day installations. To accomplish this expedited installation process, these contractors use quick-curing products known as “polyureas” or “polyaspartics.” GarageFloorCoating.com underscored in their August 2020 article titled “Polyurea-Polyaspartic One-Day Systems: Do They Work“, that speed and quality rarely intersect when it comes to concrete coatings.

In this article, we delve a little deeper and give you the tools to make the right choice when choosing a concrete coatings company.

Comparing Polyurea & Polyaspartic Coatings

Contractors trying to achieve single-day, concrete coating systems installation, employ liquid coatings called “polyureas“ or ”polyapartics”. They use them both as the primer coat (direct-to-concrete) and the subsequent top coat – a key point which makes these coverings problematic. Oftentimes, those promoting these services stress how advanced these products are due to their fast curing properties and other benefits like extreme UV resistance, stain & chemical resistance, etc….all true. However, they also malign an alternative coating called “epoxy” (simply because they don’t use them!). Their criticisms are not only wrong, they could cost you money!

So what’s the difference between a polyurea and polyaspartic concrete coating? A polyurea is a coating with an extremely short cure time that’s durable enough to coat roofs, foundations, truck beds, and other surfaces. The cure time is so short, in fact, that “true” polyureas require specialized equipment to apply it, like portable reactors. A polyaspartic is similar to a polyurea (in fact it’s an “aliphatic polyurea“), but it has been chemically modified to slow the cure rate. This allows applicators adequate time to maneuver a polyaspartic coating over the substrate with rollers or squeegees, making the overall process far more user-friendly. Although a polyaspartic is a slowed-down version of a polyurea, it’s still considered a fast cure coating relative to say, an epoxy.

The Pitfalls of Using a Polyurea-Polyaspartic As a Primer

The catch here is that due to the manner in which a polyurea-polyaspartic cures – it cannot support thick applications – only thin or moderate film builds are possible. And a polyurea-polyaspartic doesn’t penetrate raw concrete nearly as well as an epoxy. So, polyurea-polyaspartics simply aren’t designed for direct-to-concrete application – consult an architect if you need convincing.

This limitation is especially true when dealing with concrete having medium to high moisture content. Porous concrete absorbs moisture via capillary action known as “moisture-vapor transmission”. Over time, this results in hydrostatic pressures building beneath the applied coating…and thinly applied, poorly penetrating coatings delaminate over time if the hydrostatic pressure exceeds threshold. This is exactly why no “one-day” contractor fully warrants their finished coatings against ”high hydrostatic pressures” or “moisture related issues” – just review the warranty exclusions listed on their own websites!

So the question becomes: If these weren’t real concerns, wouldn’t the contractor offer a full warranty with no exclusions for moisture-related issues? This should give you pause!

Enter the Epoxy Primer

Epoxy coatings cure by way of exothermic reactions (heat-generating reactions). Unlike polyureas and polyaspartics, the way in which an epoxy cures allows for thicker application – with epoxies, the greater the mass, the faster the cure rate – which is exactly why epoxies are called “high-build” coatings! This, combined with the fact that they deeply penetrate raw concrete, provides a superior capacity to withstand high-hydrostatic pressures. It explains why epoxies are the “go-to” choice as direct-to-concrete primers among architects (…and trust-worthy contractors).

However, despite the superiority of epoxies over polyureas and polyaspartics as primer coats, epoxies do have shortcomings as well. They’re characterized by poor UV resistance (they tend to yellow under prolonged exposure to sunlight) and do not provide the extreme chemical resistance that a polyurea or polyaspartic can. Consequently, epoxies are less than ideal candidates as topcoats!

But, what if you were to combine the best properties of each coating type in a single coating system? In other words, what if you could use an epoxy as the primer coat (direct-to-concrete), add a full broadcast of flakes, and then finish off the coating system with a protective UV/chemical-resistant top coating like a polyaspartic? Wouldn’t that create the most durable coating system? The short answer…yes it would!

Theirs VS Ours

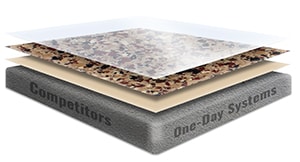

While “one-day” coating systems typically comprise three layers – (a) thin primer layer of polyurea-polyaspartic applied directly to concrete (layer 1); (b) a full-flake broadcast of thermoplastic flakes (layer 2), and (c) a single clear top-coat polyaspartic, all swiftly laid down to meet the 24-hour install requirement. Unfortunately, the end result is a wafer-thin coating system that’s prone to delamination in high moisture conditions. Why would anyone play Russian Roulette with their money!

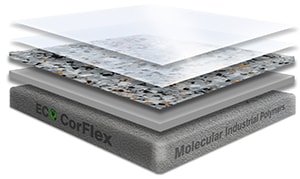

Our coating systems combine the strengths of both epoxies and polyaspartics. We start by applying our proprietary, moisture-mitigating 100%-solids epoxy as the primer coat (direct-to-concrete), followed by your choice of either thermoplastic or our unique mica-mineral flake blends, and we finish it all off with two separate coats (not one) of our 100%-solids polyaspartic…producing a four-layered system (not 3) measuring over 35 mils in thickness!

Since we use a slower-curing epoxy as the primer coat, our installation duration takes 2 days…not one…but that’s a great thing! Your finished concrete flooring will be stronger, have less chance of peeling, and (because of this) it’ll come with a genuine warranty that covers all moisture-related issues (including high hydrostatic pressure).

Far Beyond the Standard

Our full-flake concrete flooring solutions far surpass that of “1 day” systems in more ways than one:

- We use industrial-grade, 100%-solids liquid coatings only (no less than 100%-solids)

- We prime our floors with a moisture-mitigating epoxy primer (never a polyurea or polyaspartic)

- We offer more than 30 choices of mica-infused flake blends (not just thermoplastic)

- We top our systems with dual layers of our 100%-solids polyaspartic (not just one coat)

- We provide a REAL guarantee against moisture-related issues and hot-tire transfer (no fine print exclusions)

So call us, Garage Floor Coating of Nashville at (615)-878-4320, your local concrete coating system experts, for the most beautiful and durable concrete floor coatings with a REAL warranty.